Page 8 - FT SAFETY CATALOG 2017-2018

P. 8

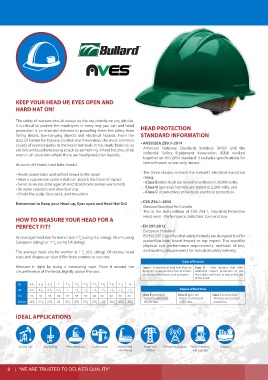

KEEP YOUR HEAD UP, EYES OPEN AND

HARD HAT ON!

The safety of workers should always be the top priority on any job site.

It is critical to protect the employees in every way you can and head HEAD PROTECTION

protection is an essential element in providing them the safety from

falling debris, low-hanging objects and electrical hazards. From the STANDARD INFORMATION

data of Center for Disease Control and Prevention, the most common

causes of severe injuries to the head that leads to traumatic brain injury • ANSI/ISEA Z89.1-2014

are falls and accidents being struck by something. A hard hat should be American National Standards Institute (ANSI) and the

worn in all situations where there are head protection hazards. Industrial Safety Equipment Association (ISEA) worked

together on this 2014 standard. It includes specifications for

As a rule of thumb, hard hats should: lateral impact, or top-only impact.

The three classes indicate the helmet’s electrical insulation

• Resist penetration and deflect blows to the head

• Have a suspension system that can absorb the force of impact rating:

• Serve as an insulator against electrical shocks (when warranted) - Class E (electrical) are tested to withstand 20,000 volts;

• Be water resistant and slow burning - Class G (general) helmets are tested at 2,200 volts; and

• Shield the scalp, face, neck, and shoulders - Class C (conductive) provide no electrical protection

Remember to Keep your Head up, Eyes open and Hard Hat On! • CSA Z94.1-2015

National Standard for Canada

This is the sixth edition of CSA Z94.1, Industrial Protective

Head wear - Performance, Selection, Care and Use.

HOW TO MEASURE YOUR HEAD FOR A

PERFECT FIT? • EN 397:2012

European Standard

3

An average head size for men is size 7 ⁄ (using U.S. sizing), 58 cm (using EN 397:2012 certifies that safety helmets are designed to offer

8

1

European sizing) or 7 ⁄ (using UK sizing). protection from lateral impact or top impact. This specifies

8

physical and performance requirements, methods of test,

The average head size for women is 7 ⁄ (U.S. sizing). Of course, head and marking requirements for industrial safety helmets.

1

4

sizes and shapes can also differ from country to country.

Types of Helmets

Measure it right by using a measuring tape. Place it around the Type I - Conventional hard hats that are Type II - New designs that offer

circumference of the head, slightly above the ears. designed to reduce the force of impact additional impact protection to the

to the top of the head, neck and spine. front, sides and back, as well as the top

of the head.

US 6 ⁄ 5 8 6 ⁄ 3 4 6 ⁄ 7 8 7 7 ⁄ 1 8 7 ⁄ 1 4 7 ⁄ 3 8 7 ⁄ 1 2 7 ⁄ 5 8 7 ⁄ 3 4 7 ⁄ 7 8 8

UK 6 ⁄ 1 6 ⁄ 5 6 ⁄ 3 6 ⁄ 7 7 7 ⁄ 1 7 ⁄ 1 7 ⁄ 3 7 ⁄ 1 7 ⁄ 5 7 ⁄ 3 7 ⁄ 7 Classes of Hard Hats

2 8 4 8 8 4 8 2 8 4 8

cm 53 54 55 56 57 58 59 60 61 62 63 64 Class E (electrical) Class G (general) Class C (conductive)

- Tested to withstand - Tested to withstand - Provides no electrical

inches 20 ⁄ 3 21 ⁄ 1 21 ⁄ 5 22 22 ⁄ 1 22 ⁄ 3 23 ⁄ 1 23 ⁄ 5 24 24 ⁄ 1 24 ⁄ 3 25 ⁄ 1 20,000 volts. 2,200 volts. protection.

4 4 8 2 4 4 8 2 4 4

IDEAL APPLICATIONS

Oil and Gas Rig Drilling Petrochemicals Construction Metal, Steel Power and Telecommunications Freight Transport Shipping

and Mining Utilities and Logistics

8 | “WE ARE TRUSTED TO DELIVER QUALITY”