Page 89 - FT SAFETY CATALOG 2017-2018

P. 89

FLAME RETARDANT WORKWEARS FLAME RETARDANT WORKWEARS

INFINITE POSSIBILITIES

This fabric blend takes PBI’s proven protective characteristics to a whole new level by combining

unmatched flame and thermal protection with unsurpassed strength and durability. PBI Matrix® is

lightweight, flexible and provides superior comfort and reliability. It gives you the power to get the

job done day after day and still remain service worthy.

Fabric Features:

• PBI Matrix® High Performance- Combines high performing heat and flame protection of PBI Gold®

with durable matrix of high strength 400 or 600 denier filaments to reduce wear and tear.

• Complies with International Standards - NFPA 2112, EN 469:2005, ISO 15025 (Flame spread),

EN ISO 9151:2016 (Convective heat), ISO 6942 (Radiant heat), ISO 17493:2016 (Heat resistance)

and EN 1149-5(Electrostatic properties).

Inherently flame and high temperature resistant fabric made from special meta-aramid fiber yarn.

The fabric is made up of aramid rings linked by aramid bonds. It is non-combustible and will not

melt or drip. When exposed to intense heat, the fabric carbonizes and thickens, forming a virtually

impenetrable barrier.

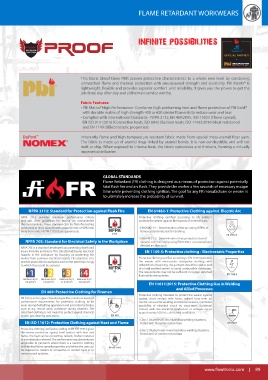

GLOBAL STANDARDS

Flame Retardant (FR) clothing is designed as a means of protection against potentially

fatal flash fire and arc flash. They provide the worker a few seconds of necessary escape

time while preventing clothing ignition. The goal for any FR manufacturer or wearer is

to ultimately increase the probability of survival.

NFPA 2112: Standard for Protection against Flash Fire EN 61482-1: Protective Clothing against Electric Arc

NFPA 2112 provides minimum performance criteria Protective clothing certified according to EN 61482-1

and sets clear guidelines for testing on instrumented protects the wearer against the hazards of an electric arc.

thermal manikins. These standard calls for flash fire testing

conducted at three seconds with a pass/fail rate of 50% total • EN 61482-1-1 - Determination of the arc rating (ATPV) of

body burn under ASTM F1930 testing protocols. flame resistant materials for clothing.

2112 EN 61482-1

• EN 61482-1-2 - Determination of arc protection class of

NFPA 70E: Standard for Electrical Safety in the Workplace material and clothing by using EN 61482-1 constrained and

directed arc (box test)

NFPA 70E is a standard developed on preventing death and

injury from fire and burns. This standard addresses electrical EN 1149-5: Protective clothing - Electrostatic Properties

hazards in the workplace by focusing on protecting the

worker from common electrical hazards. The objective is to Protective clothing certified according to EN 1149-5 provides

provide protection to workers based on the potential energy the wearer with electrostatic dissipative clothing with

to which they could be exposed. reduced risk of sparking. The garment should be used as part

of a total earthed system to avoid combustible discharges.

70E The requirements may not be sufficient in oxygen enriched

flammable atmospheres. EN 1149-5

Minimum ATPV Minimum ATPV Minimum ATPV Minimum ATPV

4 (Cal/cm²) 8 (Cal/cm²) 25 (Cal/cm²) 40 (Cal/cm²)

EN 11611:2015: Protective Clothing Use in Welding

and Allied Processes

EN 469: Protective Clothing for Firemen

Protective clothing intended to protect the wearer against

EN 469 is an European Standard specifies minimum levels of spatter, short contact with flame, radiant heat from an

performance requirements for protective clothing to be electric arc used for welding and allied processes, minimizes

worn during firefighting operations and associated activities possibility of electrical shock by short-term, accidental

such as e.g. rescue work, assistance during disasters. The contact with live electrical conductors at voltages up to

described clothing is not meant to protect against chemical approximately 100 V d. c. in normal conditions.

and/or gas cleaning operations. EN 469

• Class 1 (lower level): less hazardous welding situations.

EN ISO 11612: Protective Clothing against Heat and Flame Tested with 15 molten metal drops EN 11611

Protective clothing certified according to EN ISO 11612 gives • Class 2 (higher level): more hazardous welding situations.

the wearer protection against brief contact with heat and Tested with 25 molten metal drops

flame. The heat can be convective, radiant, molten material,

or a combination thereof. The performance requirements are

applicable to garments where there is a need for clothing

with limited flame spread properties and where the user can EN ISO 11612

be exposed to radiant or convective or contact heat or to

molten metal splashes.

www.flowtronix.com | 89