Page 15 - FT HIGH TEMPERATURE TEXTILE

P. 15

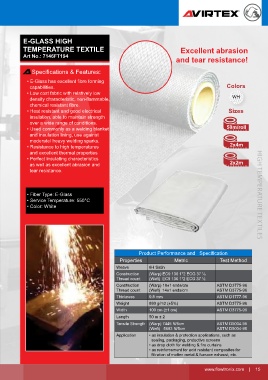

E-GLASS HIGH

TEMPERATURE TEXTILE Excellent abrasion

E-Glass General Characteristics: Art No.: 7146FT194 and tear resistance!

• High surface weight ratio Specifications & Features:

• Amorphous structures • E-Glass has excellent fibre forming

• No stretch or shrink after exposure extremely high capabilities. Colors

or low temperatures • Low cost fabric with relatively low WH

• Low moisture absorption and water resistant density characteristic, non-flammable,

chemical resistant fibre.

• No physical or chemical change in water contact • Heat resistant and good electrical Sizes

• Flexibility in the design of low price insulation, able to maintain strength

• Not flammable or oxidising over a wide range of conditions. 50m/roll

• Little or no response to most chemicals • Used commonly as a welding blanket

and insulation lining, use against

• Good thermal insulation moderate/ heavy welding sparks.

• No contact corrosion due to electrochemical effects • Resistance to high temperatures 2x4m

and excellent thermal properties

• Perfect insulating characteristics

as well as excellent abrasion and 2x2m

For higher temperature exposure, textured E-glass products are used with an tear resistance.

added high temperature treatment. An inorganic finish is applied to the surface of

the fabric, giving the fabric temperature resistance up to 750°C.

• Fiber Type: E-Glass HIGH TEMPERATURE TEXTILES

Suitable high quality insulation will minimize energy loss, lower operating costs and • Service Temperature: 550°C

improve personnel safety. All this will help lower the total cost of ownership of your • Color: White

particular equipment and facility and reduce your environmental footprint.

Resistance to High Temperatures and Excellent Thermal Properties

Product Performance and Specification

Properties Metric Test Method

Weave 8H Satin

Construction (Warp) EC9 136 1*2 ECG 37 ½

Thread count (Weft) EC9 136 1*2 ECG 37 ½

Construction (Warp) 18±1 ends/cm ASTM D3775-96

Thread count (Weft) 14±1 ends/cm ASTM D3775-96

Thickness 0.8 mm ASTM D1777-96

Weight 880 g/m2 (±5%) ASTM D3775-96

Width 100 cm (±1 cm) ASTM D3775-96

Length 50 m ± 2

Tensile Strength (Warp) 7445 N/5cm ASTM D5034-95

(Weft) 5693 N/5cm ASTM D5034-95

Application • as insulation & protection applications, such as

sealing, packaging, protective screens

• as drop cloth for welding & fire curtains

• as reinforcement for acid resistant composites for

filtration of molten metal & furnace exhaust, etc.

www.flowtronix.com | 15